Warehouse Robotics in the Future: AMRs, AGVs, and the Future of Picking

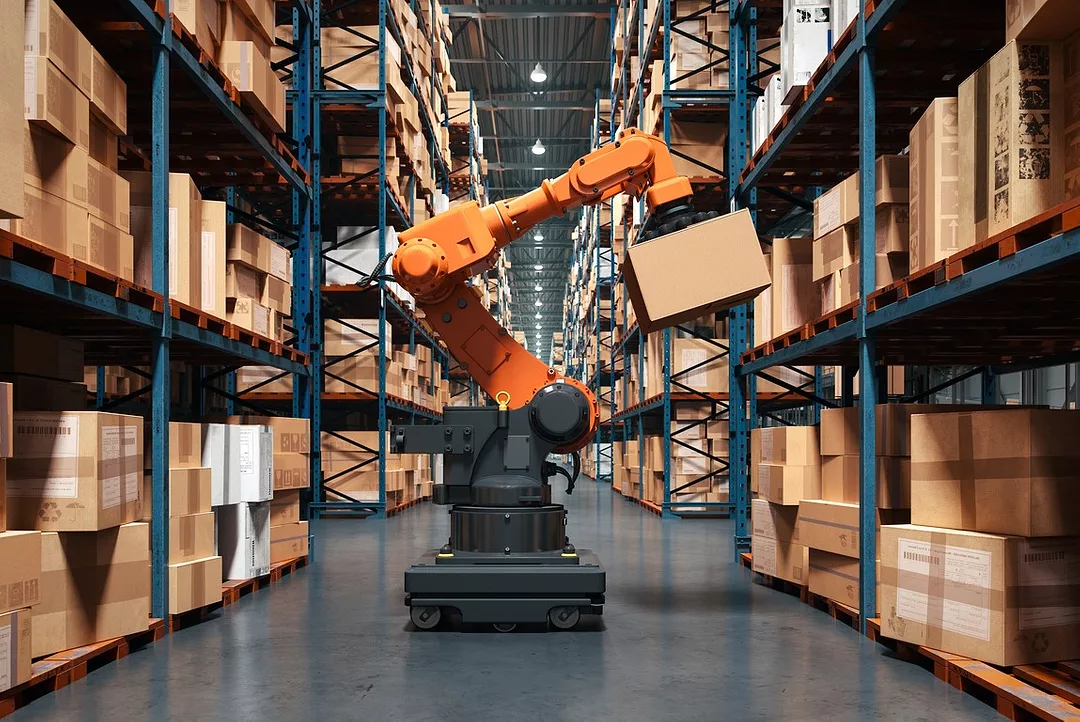

Warehousing has long ceased to be a question of space. It has become a question of speed, accuracy, scalability, and robustness. This has been due to the rise of electronic commerce, quick commerce, and omnichannel logistics, which has led modern warehousing solutions to implement robotics technology in an effort to keep up. Autonomous mobile robots, AGVs, and robotic picking solutions are changing the face of modern warehousing solutions.

This blog discusses warehouse robotics in an easy-to-understand format with an insight into where this evolving industry is headed and how businesses can prepare for this change.

Warehouse Robotics Made Easy: AMR, AGVs

What Are Autonomous Mobile Robots (AMRs)?

Autonomous Mobile Robots (AMRs) is a kind of robot that can move around the warehouse on its own using sensors, cameras, and software. Unlike other automation solutions, AMRs do not require predefined routes or guides.

They can:

- Detect obstacles in real time

- Reroute themselves dynamically

- Work safely alongside human workers

This flexibility makes AMRs ideal for dynamic warehouse environments, especially in Grade A warehouses designed for scalability.

What Are Automated Guided Vehicles (AGVs)?

Automated Guided Vehicles (AGVs) follow predefined paths using magnetic strips, QR codes, or wires embedded in the floor.

Characteristics of AGVs:

- Most suited to repetitive transport routines

- Stable and Predictive Movement

- Less complex software than in AMRs

AGVs are suited to high-volume warehousing where the environment tends to remain static.

Comparison of AMRs and AGVs

| Feature | AMRs | AGVs |

| Navigation | Dynamic and flexible | Fixed routes |

| Adaptability | High | Limited |

| Setup time | Quicker | Longer |

| Ideal use | Modern, evolving warehouses | Repeat automation of traditional tasks |

Both have their role in relation to the future of automated warehouse operations.

The Progression in Picking Technology in Warehouse Environments

Warehouse picking has advanced from traditional manual picking to robot-assisted picking.

How Pick and Place Robots Function

Modern picking robots incorporate:

- Use of Artificial Intelligence to Identify Objects

- Machine learning algorithms for accuracy enhancement

- Computer vision technology for recognizing shapes and packages

These technologies allow for automatic fulfillment, fewer errors, as well as higher pick rates.

Robots now do the following:

- Piece picking

- Goods-to-person systems

- Sorting and consolidation

It directly enhances the efficiency of warehousing and the turn-around time for orders.

Advantages of Robotics Implementation in Warehouse Operations

Integrating robotics can bring the following advantages:

- Increased throughput and faster order fulfillment time

- Less dependence on manual labour

- Enhanced work safety

- Performance during peak seasons

- Improved use of space in massive storage complexes

Robotics can also accommodate scalable warehouse infrastructure, which is an important requirement for logistics tenants.

Issues in the Implementation Process of Warehouse Robotics

Though there are benefits for companies, there are actual challenges for businesses:

Key Implementation Challenges

- High initial investment

- Existing Warehouse Management System Integration

- Need for skilled technicians

- Inadequacies of the layout in old structures

Nonetheless, many of these issues are relatively easily overcome in the case of custom-built warehouses that are designed with automation in mind.

Human Workers and Robotics: Working Together

One common misconception is that robots replace people.

In reality,

- Robots are used for repetitive and heavy work

- Humans perform supervision, exception management, and quality monitoring

Such interaction enhances productivity and develops safer and more adept Jobs in warehouses.

Environmental Impact of Warehouse Robotics

The warehouse robots can help in terms of:

- Minimizing energy waste by efficient body movement

- Reducing error-related returns

- Supporting electric and low-emission operations

When paired with efficient building design, robotics is a contributor to sustainable warehousing.

Future Trends in Warehouse Robotics

What the Future Looks Like

Industry analysts forecast:

- Fast-paced development in AI-based warehouse automation

- Wider adoption of robotic picking solutions

- More intelligent AMRs with decision-making abilities

- Robotics-ready infrastructure to be standard in warehouses

FAQs

1. Is Warehouse Robotics Only For Large Companies?

A. No. Robotics is now more modular and scalable and can be applied at the mid-range level.

2. Are AMRs safer than manual material handling?

A. Yes. AMRs come equipped with sensors for collision avoidance as well as safety mechanisms that prevent injuries.

3. Do robots work in all warehouse layouts?

A. Robotics works effectively in a contemporary warehouse that has open aisles, power availability, and computerized systems.

4. What is the time frame for realizing ROI?

A. Some businesses can see a return on investment in as little as 18 to 36 months depending on volume and automation.

Tips for Businesses Considering Warehouse Robotics

- Begin with process mapping prior to automation

- Pick robotics platforms based on work flows, rather than on what’s trending

- Invest in Robotics-Ready Infrastructure

- Scalability Planning for the Future

Conclusion

Warehouse robotics prospers in an environment designed for scaled success, innovation, and efficiency. At Scalar Spaces, we design and develop Grade-A and BTS warehouse parks that enable technology such as AMRs, AGVs, and intelligent picking technology.

If you are planning for the future of logistics, it is the right time to integrate the warehousing strategy with automation-ready infrastructure.

Learn how Scalar Spaces can assist you with smarter, future-ready warehousing and follow us on Instagram, LinkedIn.