The Role of a WMS in the Modern Warehouse

A Warehouse Management System is one of the most effective tools when it comes to operating in the current fast-paced logistics industry where warehouses have evolved from simple storage facilities into activity hubs of the future. Scalar Spaces, businesses operating Grade A and built-to-suit warehouse hubs, optimizing the operations of these structures is of the utmost importance.

A WMS is software used to manage warehouse operations such as inventory tracking and locating, and also guides the picking, packing, and shipping of the inventory. Whether you are a beginner or an experienced user, learning about the uses of warehouse management could be an eye-opening experience.

Characteristics of Modern WMS

Presently, modern WMS solutions are supported by a variety of functionalities that are much broader than inventory management.

- Real-Time Inventory Tracking: Understand exactly what your inventories are, where they are, and how they move among multiple warehouse locations.

- Smart Picking & Order Fulfillment: Efficient methods of order picking, such as batch pick, wave pick, and zone pick, with the help of bar code scanning and RF scanning for accuracy purposes.

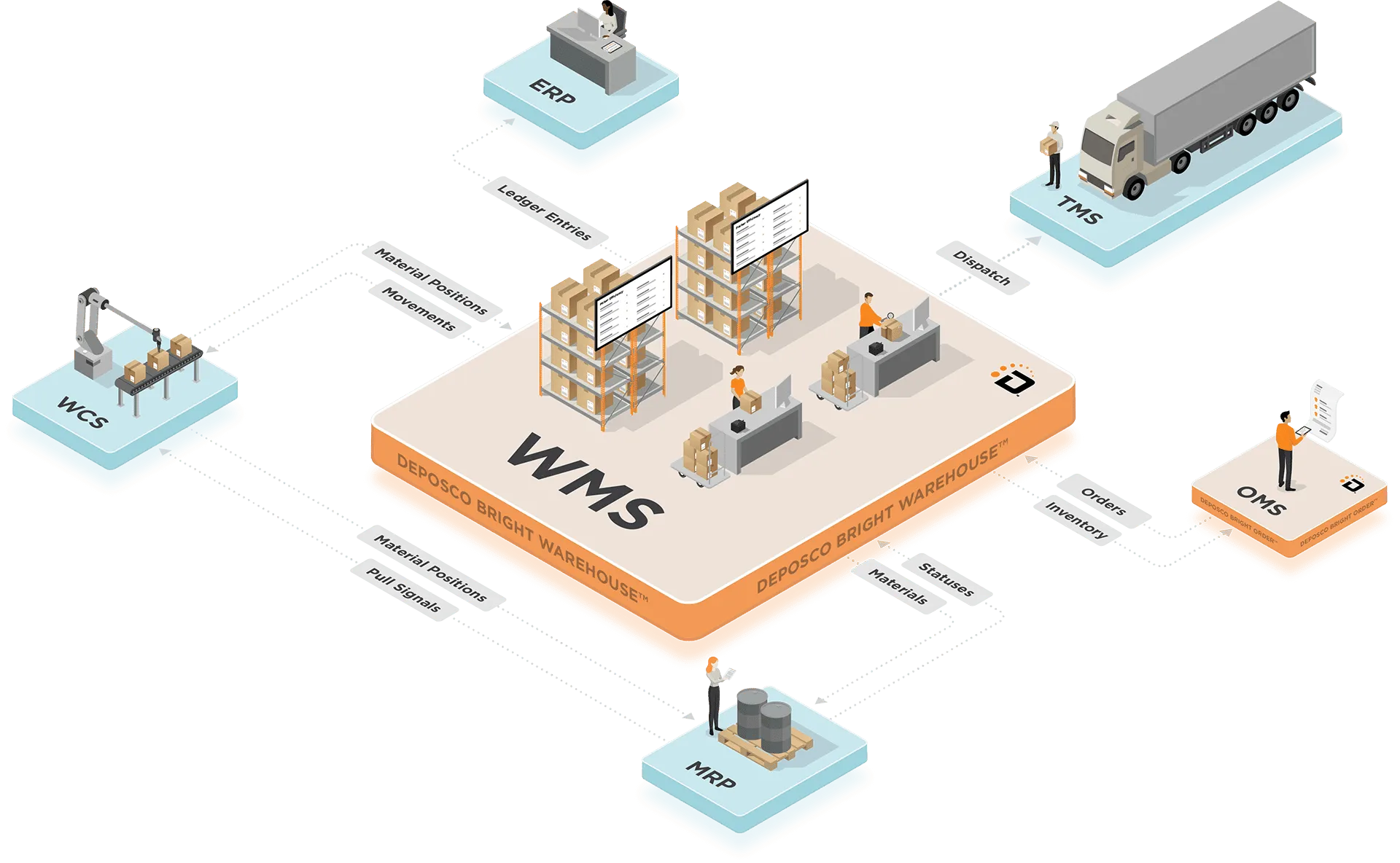

- ERP & TMS Integration: Make effortless integration with other business systems so that data flow from ordering through shipping can be smooth.

- AI Analytics & IoT Integration: Best-of-Breed WMS offerings enable demand forecasting and optimized storage allocation with some even directing automated material handling.

- Space Optimization & Layout Planning: It aims at maximizing the storage capacity of the warehouse by optimal allocation of locations based on size and demand.

Advantages of a WMS Implementation

- Enhanced Accuracy: Minimize mistakes in placement or stock with real-time information and automated reporting. Accuracy has increased by 99.9 percent in many warehouses.

- Reduces Operational Costs: By automating the processes that were handled manually by humans, the operational costs will be lowered since there will be a lesser workforce.

- Faster Order Fulfillment: Optimized pick routes and processes result in faster handling, faster shipping, and ultimately satisfied customers.

- More Effective Use of Space: WMS maximizes space utilization, thereby preventing the need to add additional space.

- Scalability: A contemporary WMS will scale with your business, dealing with higher or varying volumes of business proficiently.

How WMS Increases Efficiency & Accuracy

The WMS optimizes day-to-day warehousing activities by :

- Routing workers on optimal pick paths.

- Minimizing Mis-picks and Returns

- Optimize warehouse layout to reduce waste area.

Labour productivity has been seen to improve by 15-40%, stockouts by 30–60%, and inventory-carrying costs by 12-25% by organizations that implemented WMS.

Common Misconceptions about WMS

- “WMS is for large warehouses.”

Small warehouses can benefit too from real-time tracking and efficient workflow processes. - “WMS solves all problems automatically.”

Trained personnel and optimized processes are needed. - “WMS is just inventory software.”

It also handles fulfillment, labour, analytics, and integration. - “Implementation is too complex.”

Roll-out and training can make the process easier.

Metrics to Measure WMS Success

Tracking performance is critical. Key metrics include:

- Inventory Accuracy: Correctly recorded stock vs. physical stock.

- Order Cycle Time: Time from order receipt to dispatch.

- Picking & Packing Productivity: Units picked or orders fulfilled per shift.

- Labour Cost Reduction: Comparing pre and post-WMS labour costs.

- Stockout & Overstock Rate: Frequency of out-of-stock or excess stock.

- Customer Order Accuracy: Orders shipped correctly the first time.

- Space Utilization: Efficient layout usage.

- ROI: Savings from reduced labour, errors, and storage vs. implementation costs.

Metrics to Measure WMS Success

Performance monitoring is significant. Some of the most important indicators of performance include

- Inventory Accuracy: Actual stock versus recorded stock.

- Order Cycle Time: Order reception to dispatch.

- Picking & Packing Productivity: Units picked per shift, orders fulfilled per shift

- Reducing Labour Cost: Comparison of pre-and post-implementation of WMS labour costs.

- Stockout & Overstock Rate: Frequency of out-of-stock and overstock.

- Customer Order Accuracy: The order is processed correctly on its first shipment.

- Space Utilization: Effective usage of space.

- ROI: Cost savings due to reduced manpower, errors, and storage costs compared to costs of implementation.

Real-World Success Stories

- E-commerce warehouse: Cloud-based WMS can integrate seamlessly with e-commerce, and increased picking efficiency of up to 40% and accuracy rates over 99% have often been observed because of better practices such as smart picking and automated cycle counts.

- Food & Beverage: WMS, particularly combined with sensors enabled with IoT (such as temperature/humidity sensors), is instrumental for FIFO compliance. It is instrumental for reducing waste because older products are discharged first, which is significant for handling perishable goods.

- Pharmaceuticals: The use of AI-based WMS is implemented for managing complicated inventory, enhancing the process for ordering, and ensuring compliance. Improved efficiency in ordering and managing inventory is generally attributed to advantages offered by AI and automation.

- Small 3PL Provider: A lightweight or cloud WMS can prove to be very helpful for SMEs to efficiently manage diverse SKUs efficiently. The capacity to efficiently use labour resources often leads to very significant labour costs savings, quantified in the range of 15 to 20% in most cases.

How Small Businesses Can Leverage WMS

Even smaller warehouses can reap WMS benefits:

- Use cloud or SaaS WMS to reduce upfront costs.

- Start with core features: inventory tracking, order management, picking optimization.

- Integrate gradually with other platforms like ERP or e-commerce systems.

- Use basic automation such as barcode scanning or mobile apps.

- Track simple metrics like inventory accuracy, picking speed, and order accuracy.

The Future of WMS Technology

WMS is changing rapidly, with developments such as:

- AI & Machine Learning: Predicting Demand & Optimizing Storage.

- IoT Integration: Smart Shelves and Asset Tracking.

- Robotics & Automation: Use of AGVs & robots in combination with WMS.

- Cloud & Mobile Solutions: Remote access capabilities that improve usability when operating across several locations.

FAQs

1. What are the cost savings of using WMS?

A. Reduced labour costs ranging from 10-45%, accuracy, lower inventory costs, and quicker fulfillment result in return on investment within 12-24 months.

2. Can WMS systems be used in smaller and medium-sized warehouses too?

A. Yes. The latest systems from MMS are scalable and modular. This is an ideal solution for warehouses of varying sizes.

3. Can WMS help make warehouse operations more sustainable?

A. Yes. By optimizing space, inventory, and workflows, WMS reduces waste, lowers energy use, and improves resource efficiency, making operations both cost-effective and eco-friendly.

4. How does WMS handle sudden spikes in demand or peak seasons?

A. Modern WMS platforms use real-time analytics and demand forecasting to allocate labour, optimize picking, and manage inventory efficiently. This ensures smooth operations even during high-volume periods without additional staff or costly errors.

Conclusion

A Warehouse Management System is no longer optional, it’s a strategic tool that transforms warehouses into efficient, accurate, and scalable operations. By reducing mistakes and optimizing space as well as labour resources, a WMS is something that can provide amazing results.

If you are interested in learning more about what a WMS can do to enhance your warehouse operations, please check out Scalar Spaces for more information about our Grade A and Build-To-Suit warehouse facilities. Follow Scalar Spaces on Instagram and LinkedIn for industry insights and success stories from our industry-leading warehouses.